Top Benefits of Using Genuine UPC Bearings for High-Temperature Applications

Author:DMAG Bearings Release times:2025.07.29

Author:DMAG Bearings Release times:2025.07.29

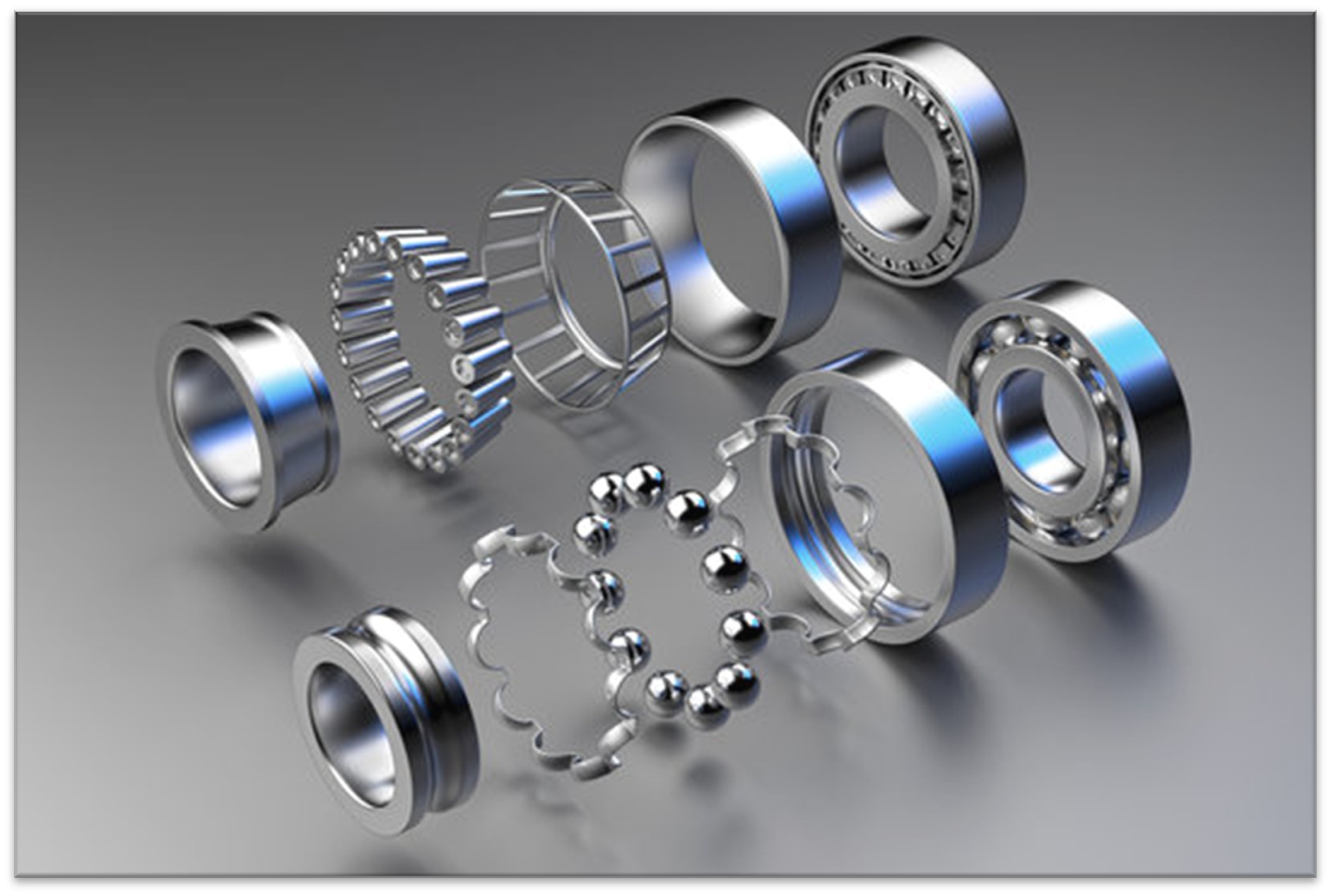

High-temperature industrial environments require components that can withstand extreme conditions without compromising performance. Bearings, in particular, play a crucial role in ensuring the smooth and efficient operation of machinery. One of the most reliable solutions in this context is the use of genuine UPC bearings. Designed for durability, strength, and precision, these bearings are ideal for high-heat settings across various sectors. This article explores the top benefits of using genuine UPC bearings for high-temperature applications, helping engineers and procurement professionals make informed decisions.

Bearings are essential in reducing friction and supporting rotational movement in machines. However, not all bearings are suitable for high-temperature operations. Environments with excessive heat can degrade standard bearings, causing lubrication breakdown, dimensional instability, and eventually equipment failure. That’s where specially designed high-temperature bearings like UPC bearings come into play.

One of the standout features of UPC bearings is their ability to function effectively under high thermal stress. These bearings are manufactured using high-grade materials such as stainless steel or chrome alloy with specialized heat-resistant treatments. In operations like steel mills, glass manufacturing, and industrial ovens—where temperatures can exceed 200°C—UPC bearings maintain their structural integrity and performance.

Industrial equipment maintenance tips often emphasize the importance of choosing heat-resistant components, and UPC bearings consistently meet this requirement.

High-temperature environments often accelerate wear and tear, reducing the lifespan of ordinary bearings. UPC bearings, however, are engineered to endure. They incorporate advanced lubrication technologies and surface treatments that prevent rapid degradation. This not only extends the service life of the bearing but also minimizes downtime, repairs, and replacement costs.

An extended service life means more predictable maintenance schedules and less unplanned disruption to operations, making them a cost-effective investment over time.

In industrial settings, machines frequently operate under heavy loads. Standard bearings might falter when exposed to both high loads and high temperatures. UPC bearings are designed with reinforced internal structures that maintain performance under such extreme conditions.

They provide excellent radial and axial load support, ensuring that machinery can operate at optimal levels without the risk of mechanical failure. This makes them ideal for use in heavy-duty equipment used in mining, power generation, and metallurgy.

Machines equipped with UPC bearings tend to run more smoothly due to their precision engineering and reduced internal friction. This improved efficiency translates into less energy consumption and better overall performance of the machinery.

In manufacturing environments where every second counts, the use of reliable bearings can significantly influence productivity. Less friction also means less heat generation, indirectly helping to regulate the machine’s temperature during operation.

High-temperature environments are often coupled with exposure to harsh substances such as dust, chemicals, or corrosive agents. UPC bearings are equipped with seals and shields that resist contamination, ensuring uninterrupted performance.

This resistance makes them suitable for industries like chemical processing, cement production, and food manufacturing, where exposure to aggressive environments is common. Maintaining bearing integrity in such conditions is vital for ensuring safety and product quality.

When exposed to high heat, many materials expand or deform, leading to loss of precision and mechanical failures. UPC bearings are manufactured with alloys and processes that ensure dimensional stability even when temperatures fluctuate dramatically.

Consistent dimensional stability is key in maintaining the alignment of rotating shafts and minimizing vibration. This feature is particularly important in equipment that requires high precision, such as CNC machines and robotics.

Genuine UPC bearings are produced in compliance with internationally recognized standards such as ISO, DIN, and JIS. This ensures not only consistent quality but also compatibility with global machinery and industrial systems.

Compliance with these standards gives engineers and procurement managers confidence that the products meet safety, reliability, and efficiency requirements across various sectors.

Another significant benefit of using UPC bearings is their wide availability in different sizes and configurations. This makes them versatile for use across numerous applications—from automotive to aerospace and from agriculture to packaging industries.

Additionally, sourcing high temperature bearing suppliers online has become increasingly convenient, allowing businesses to reduce lead times and inventory costs by purchasing directly from verified distributors.

Although high-temperature bearings may carry a higher initial price tag, they offer a high return on investment. The reduced need for frequent replacement, lower maintenance costs, and increased machine uptime all contribute to their cost-effectiveness.

Industries focusing on long-term operational reliability will find that UPC bearings pay for themselves over time through reduced operational disruptions and extended equipment lifespan.

Reliable UPC bearing suppliers typically provide extensive technical support to guide customers through product selection and installation. Access to knowledgeable professionals helps ensure that the right OEM Bearing Suppliers for Industrial Applications type is used for the correct application, which is critical in high-heat environments.

Whether it’s selecting the right grease or understanding load dynamics, expert support can make a significant difference in achieving optimal performance from your bearings.

Choosing the right bearing for high-temperature applications is crucial for safety, efficiency, and cost savings. Genuine UPC bearings offer superior heat resistance, dimensional stability, extended service life, and reliable performance under stress—all of which are essential for demanding industrial environments.

For those looking to invest in authentic, high-quality UPC bearings, DMAG Bearings stands out as a dependable partner. With a broad product range, compliance with international standards, and a team of experienced professionals, the company ensures durable, cost-effective solutions tailored to meet diverse industrial needs. Explore their offerings today to find the perfect fit for your application.