Tips for Selecting the Right Bearing Supplier for Complex Industrial Needs

Author:webmaster2019 Release times:2025.08.20

Author:webmaster2019 Release times:2025.08.20

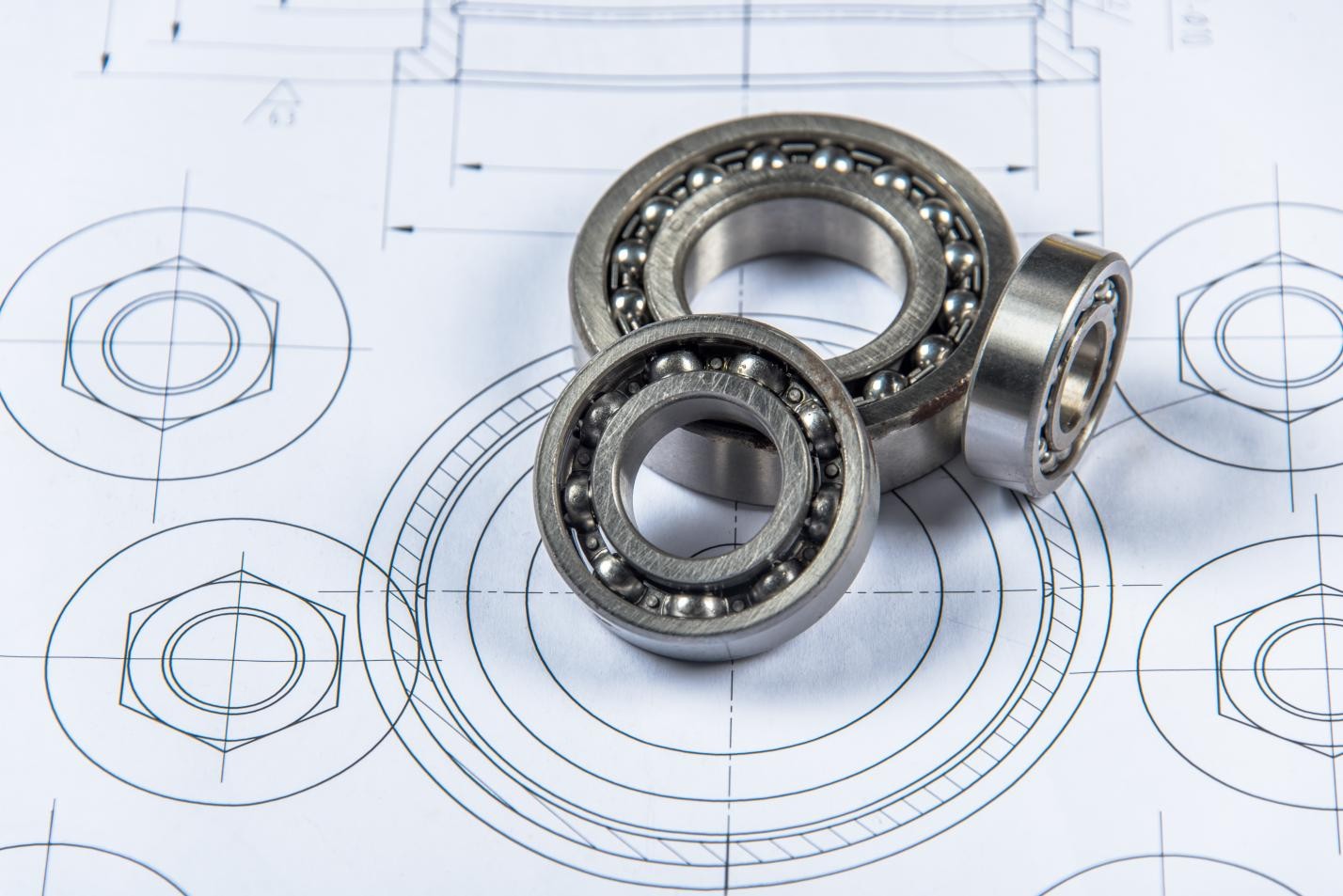

Then it is vital to select a supplier of bearings in business industries where precision is important. The bearings are important in facilitating ease of operation, cutting down friction, and increasing the life of machines. When companies cooperate with reliable bearing manufacturing firms, they are assured that they get high-quality components working at acceptable standards. When one is in need of Miniature Precision Ball Bearings or any other specialized product, it can be directly attributed to efficiency and resulting costs in machines, as well as avoiding unnecessary roadblocks in industry.

As the first step to select a stable bearing manufacturing company, one should get to know your requirements accurately. Each industrial purpose is unique in its demands, be it fast rates of operation, large loads or restricted areas. Knowing the right kind of bearings, either Miniature Bearings on sale or the normal ball bearings, guarantees compatibility and optimum usage. Technical description, material quality, and operational limits assessments can avoid untimely failures and make the workplace highly productive in challenging industrial settings.

The determinants in selecting a bearing manufacturing company are experience and reputation. The suppliers having of experience in the industry tend to give better advice, bespoke solutions, and quality products. The credentials of the supplier can be a way of checking certifications, industry partnerships, and testimonials from clients. The supplier who has some experience in the field of working with linear ball bearing is also able to give ideas and recommendations on alternatives and enhancements that can be used according to the aims of your project.

The price is an area of concern, but it cannot be lowered at the expense of quality when choosing a bearing manufacturing firm. Bearings at low prices may be cheap in the short term, but may result in tank replacements and undesirable machine crashes. In the selection of options, beware of durability, performance, and the supplier’s support. The major aspects to be mindful of are:

Product range and availability, including Miniature Precision Ball Bearings

Other important parameters of a bearing manufacturer company are timely delivery and inventory maintenance. Companies usually depend on constant production, and the Miniature Bearings for sale may disrupt the production rhythms. Selection of suppliers who have good logistics, adequate storage facilities and quick shipping would keep the downtime minimal. Furthermore, the suppliers who provide consulting services regarding the choice of linear ball bearings may ensure stable operating efficiency and mitigate possible risks related to the usage of the wrong parts.

Communication and support distinguish top suppliers from average ones. A responsive bearing manufacturing company can answer technical queries, provide installation guidelines, and address emergency requirements. In cases where manufacturing firms have invested in precision machines, the presence of knowledgeable representatives will streamline the businesses and avoid instances of costly mistakes. Procurement of Miniature Precision Ball Bearings (and other larger parts) is also essential to ensure the long life of machinery and overall safety in the work environment.

Choosing which bearing supplier is best to use involves good considerations about the quality of their product, experience, technical support, as also reliability. It is proper to have the supplier provide a series of Miniature Bearings to buy and specific versions, such as linear ball bearings, which will promote effective operations and minimize maintenance challenges. DMAG BEARINGS can be characterized as an outstanding company in terms of professionalism, high-quality products, and adherence to the needs of businesses that have complicated requirements in the industrial setting.